Microlens Arrays: How they Differ and How they are Fabricated

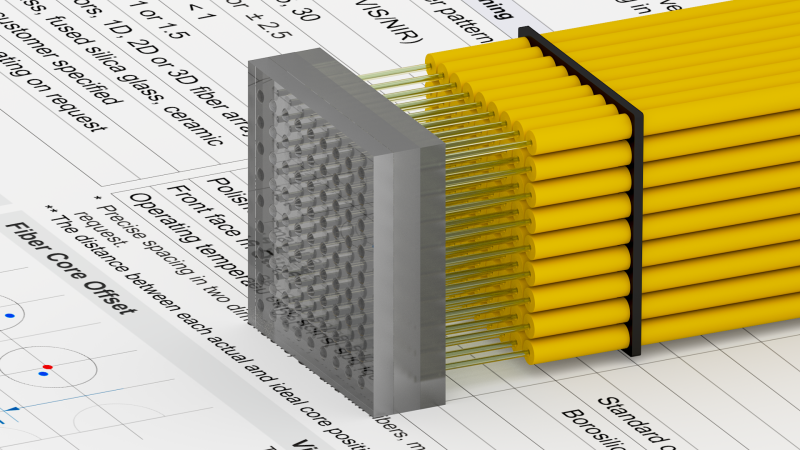

Microlens arrays are arrays of small lenses that form a periodic pattern of square or hexagonal type. Often, the outer transverse shape is square or potentially rectangle or circle. Microlenses can come in thousands or even millions. They are available as separate optical components. They are usually equipped with anti-reflection coatings on both sides. In some instances, the lenses come as a thin transparent structured layer contacted to flat homogenous glass or semiconductor substrate.

Some micro lens arrays are part of a bigger assembly. For instance, some CCD and CMOS image sensors have a microlens per photodetector to increase light collection efficiency. Incident light must be concentrated to the active areas that cover just a part of the chip area.

How Microlens Arrays Differ

Microlens arrays can differ in some ways such as the following:

- Geometrical shape. Microlenses are often circular; however, some are also cylindrical. Even lenses that focus in both directions can have a square shape.

- Optimization for various spectral ranges. The arrays can be optimized for visible light and/or part of the near-infrared. Such impacts the choice of optical material and the anti-refection coatings.

- Availability of lens pitch values. These values are available from a few micrometers to hundreds. For some applications, the lens position must be highly accurate.

- Desirability of the large fill factor. The fill factor refers to the ratio of the total area of usable lens apertures to the total area of the array. For instance, the fill factor of a square array of circular lenses that have no space between them would be π/4≈ 78.5%. For hexagonal arrays, a higher fill factor is expected.

- Each microlens is characterized by its diameter and focal length. The focal length’s homogeneity over the full device area can be essential. Also, optical aberrations can be relevant for imaging applications.

How the Arrays are Fabricated

Often, lens arrays are produced with a micro-fabrication method that forms all microlenses in one production step. For instance, a photolithographic method can be employed where a photolithographic mask defines the lens. In the area of plastic optics, mechanical techniques like molding can be applied.

Sometimes, the phenomenon of surface tension is used to get smooth and repeatable lens surface shapes. This leads to a non-spherical surface which may not be ideal in terms of optical aberrations. Moreover, the laser material processing method can also be applied to form just one lenslet at a time or some number of them using several processing beams. This offers significant flexibility, although it is slow and expensive.

Comments are closed.